If you purchased a new mower or two this spring, by now you’ve had a chance to grade performance. No doubt, some new owners are as pleased as they can be with their purchases. Others may question whether or not they made the right choice.

No matter what brand mower you operate or how old it is, getting the best performance you can from that machine is more involved than “firing it up” and seeing what it will do in the field. Achieving optimal performance from any mower requires matching it to the application, making sure operators are thoroughly trained, and following a regular preventive maintenance schedule.

No matter what brand mower you operate or how old it is, getting the best performance you can from that machine is more involved than “firing it up” and seeing what it will do in the field. Achieving optimal performance from any mower requires matching it to the application, making sure operators are thoroughly trained, and following a regular preventive maintenance schedule.

To ensure optimum performance next year means repeating the above scenario, and doing some off-season inspection and repair, if necessary. With that said, let’s see if we can raise the performance and satisfaction level of your mowing equipment.

1 — Start with Application

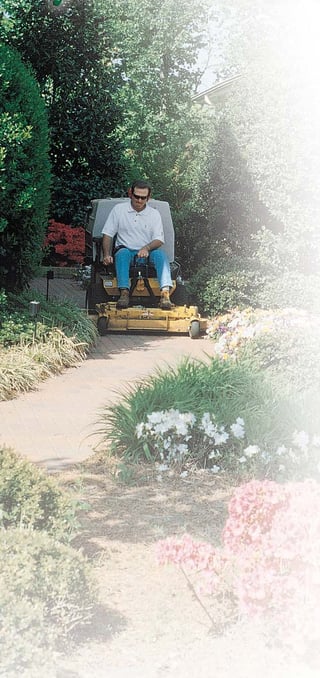

Just as contractors have market niches, mowers have application niches. Mower type (e.g., walk-behind, compact zero-turn or outfront rider), engine type/size and deck configuration/width all help define a machine’s capability. In most instances, contractors who work in hilly terrain would be better served by a walk-behind than a riding mower. Conversely, those with more level, expansive turf areas would fare better with a rider. Similarly, heavily landscaped areas need a machine that is maneuverable with plenty of trimming capability — an application for which Walker Mowers have excelled over the years.

To get the best performance from your mower, start by looking at the big picture and envision how your mower will be used. Then, take the matching exercise a step further. Deck size is important, and not just for maximizing cutting width. Wider decks, for example, are more susceptible to scalping in undulating turf than their narrower counterparts. Lighter, smaller decks are more susceptible to bouncing over the turf at higher mowing speeds.

Mowing operators can enhance their mower’s performance by matching deck type to the application, too. If property owners prefer that you mulch clippings, equip your mower with a dedicated mulching deck. The same theory applies to collecting and sidedischarging clippings. There are several multiple-function decks on the market, but operators generally can’t beat a dedicated deck for performance; one that is specifically designed for a given application.

Consider engine size and type, as well. There’s nothing more frustrating for a contractor than to purchase a new mower and then discover that it is underpowered for the application. Most manufacturers will give you a range of engine sizes from which to choose. Whereas, there is little justification to buy extra horsepower and never use it, there is all the reason in the world to have adequate power reserves when the job and conditions call for it.

The first step toward optimizing your mower’s performance is to select the right mower for the application, and outfit it to get the job done.2 — Train for Operator Efficiency

As with most equipment, there is a “right” and “wrong” way to operate a mower. And there is the most efficient way. In the beginning of the season, show employees how to operate their equipment in a productive and safe manner. Then, as the season wears on, make sure they haven’t developed any bad habits. When new employees come on board, make sure they attend an orientation session on mower operation.

Most mower manufacturers offer operator training materials to aid in training, e.g., Walker Manufacturing offers an Operator Training Video with both English and Spanish versions available.

The key to successful training, though, is consistency. Reviewing operating procedures with all employees all season long will help ensure that operators understand how to get the best performance from their equipment. This brings up another important point. Operators who use the same equipment every day get to know a machine’s idiosyncrasies, and will have a better opportunity to get top performance from that machine… every day

3 — Maintain for Performance

It is common knowledge that preventive maintenance will reduce downtime. It will also help enhance the performance of your mower. Something as simple as checking tire pressure and blade height will help ensure that your mower delivers an even cut.

Preventive maintenance practices fall into two categories: daily maintenance and interval service. Every day, for example, you should clean your mower deck housing and remove clippings and leaves from belt areas, air intakes and engine shrouds. You should also check the air cleaner for dirt buildup, engine oil level, and the function of all safety switches and operator controls. Listen for any abnormal noises, and simply give your mower a “once over” to tighten any loose parts.

Your Operator’s Manual will spell out mower interval service requirements. Following its guidelines is one of the easiest ways to help ensure that you will continue to receive top performance from your mower. Among “things to do,” your manual will explain when to change engine oil and filter, air filter, spark plugs and transmission oil. It will also offer guidelines for cleaning components and making adjustments.

4 — Inspect and Clean for Next Year

The season is far from over. Storing your equipment is probably the last thing on your mind. But what you do after the last leaf is picked up this fall will help determine your mower’s level of performance next spring.

Just as a rule of thumb, all mowers should be thoroughly cleaned, preferably with a pressure washer, to remove grass; this is important for more than aesthetics. Grass leaves behind an acid that eats away at the deck and deck parts. After washing, lubricate all grease fittings. Change the engine oil and filter, and drain the fuel tank and refill with fuel that has been mixed properly with a fuel stabilizer. After adding new oil and fuel, run the engine for a few minutes.

Engines that are unused for long periods of time can seize or “stick” if not stored away properly. Refer to the engine manufacturers’ instructions to prepare the engine for storage (if unused for two months or more). Don’t forget the battery. Make sure to remove it and clean the cable ends. Charge the battery before storing it in a dry, warm place.

With air-cooled engines, it is important to pull the engine out of the machine, remove cooling shrouds and thoroughly clean the cooling system. Likewise, the radiator and cooling fan on water-cooled models should be completely inspected and cleaned.

If this seems like a lot of work, find out if your dealer offers an offseason maintenance and inspection program. For a pre-established price, most will inspect your equipment and ready it for storage and the next season. The process identifies any problems that may be on the horizon, gives the contractor the opportunity to have it fixed before next spring, and ensures that the mower will run at peak performance when it is called into duty.

Match, train, prevent and inspect — four ways to get the best performance out of your mowing equipment. It all starts at the beginning, however. You have to make the right buying decision for your operation. If you’ve purchased the wrong mower for the application, it will never live up to your expectations no matter how fastidious you are about training employees, changing the oil and preparing it for next spring.

Site Search

Site Search