We’re not bashful about saying that Walker Mowers equipped with GHS decks are among the most effective tools for collecting grass clippings and leaves in the industry. The challenge for most Walker users is not picking up debris, but finding a time-saving and cost-effective way to handle it once it has been collected.

Walker Mfg. commissioned an independent research firm to conduct a survey to determine how Walker owners and operators handle their debris. The survey asked users, among other things, to identify their method of handling debris, their mode of transporting debris, where they take it, how far they travel, and how much, if anything, they pay for dumping it.

Nearly 400 Walker owners and operators responded to the survey. Their responses lend insight into how Walker users, including contractors, municipalities and homeowners, handle their debris, all while providing a base of comparison for all Walker users around the country.

Survey Highlights

Survey Highlights

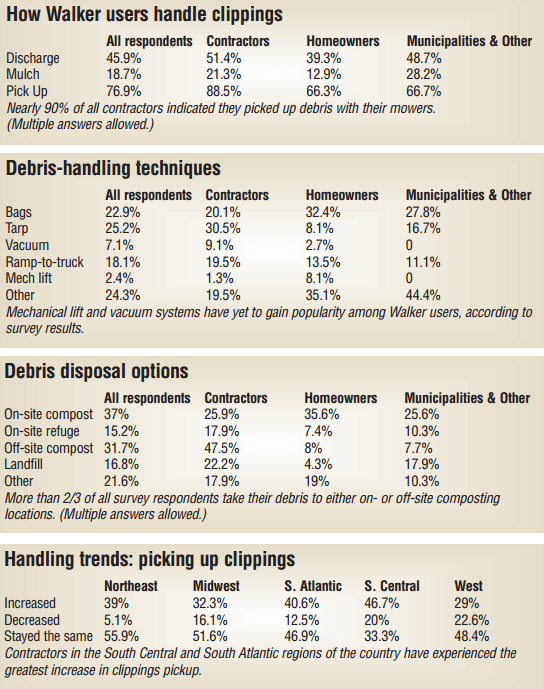

More than 75% of all Walker owners/operators use their mowers to pick up debris. According to survey results, contractors are more likely to use their Walker’s debris-handling capability than other users. In fact, nearly 90% of all contractors indicated they picked up debris with their mowers compared to 2/3 of the other respondents.

Contractors reported using their GHS decks 65% of the time, compared to homeowners (58%) and municipalities and other users (48.3%).

Midwest contractors are more likely to side-discharge clippings than contractors in other parts of the country. In fact, they reported using their side-discharge decks 50% of the time, a figure that is well above side-discharge use in other parts of the country. Conversely, South Atlantic contractors find mulching to be more effective than their counterparts in other regions. According to survey results, they mulch 30% of the time. Western contractors spend the most time (80%) with their GHS decks.

The survey asked users if they could identify a collection trend. More than 50% of all respondents indicated that the number of properties at which they pick up clippings has stayed the same over the last two years. For those who reported a trend, picking up clippings increased by nearly 3:1 over mulching/discharging. Contractors in the South Central and South Atlantic regions of the country experienced the greatest increase in clippings pickup.

To Compost or not to Compost

Clippings and leaves are likely to end up in one of two places, according to respondents — either in an on-site or an off-site compost location. Nearly 50% of all contractors cited off-site compost facilities as the most likely place to dispose of debris. More than 1/3 of homeowner respondents and 1/4 of municipalities and “other” respondents favored on-site compost locations. Less than 20% of the respondents reported disposing of debris in landfills.

Several Walker operators took advantage of alternative dumping sites, including farmers’ fields (clippings used for cattle fields), gardens for mulch (a homeowner favorite) and city curb-side pick-up. One reported taking his grass clippings to a local winery where it is composted and used in the vineyard.

The issue of how to handle debris seemed more challenging to survey respondents than where to take it. A very low percentage (only 10%) of contractors reported employing a mechanical lift or vacuum system to handle debris. Tarps, bags and barrels carried the day and the debris for the majority of contractors and all Walker users.

The issue of how to handle debris seemed more challenging to survey respondents than where to take it. A very low percentage (only 10%) of contractors reported employing a mechanical lift or vacuum system to handle debris. Tarps, bags and barrels carried the day and the debris for the majority of contractors and all Walker users.

Twenty percent of contractors, however, took some of the elbow grease and back pain out of handling clippings by employing a ramp-to-truck dumping system.Those few who used vacuums and mechanical dump devices reported even more time and money savings.

“I was going to be a one-man band when I started mowing lawns a few years ago,” relates survey respondent Harvey Jackson, owner Jackson Lawn Care Inc., Longmont, Colorado. “Now I employ six people, have four Walker Mowers and two Debris Systems’ combination equipment and debris hauling trailers.

“We collect 80% of the grass we cut. On one location alone we mow 19 acres. I figure using the debris trailer saves us at least two hours a day in clippings’ handling time and travel time, since it holds several cubic yards of debris.”

As Jackson explains, the operator simply dumps clippings into a hydraulic lift bucket. The bucket, then, travels up the side of the enclosed portion of the trailer and deposits clippings into a large holding bin. A scissor hoist lifts the bin for debris unloading. The system, he adds, transports both debris and his equipment. As he puts it, “I can’t imagine mowing grass without it.”

Larry Linehan, owner Linehan Landscaping & Property Maintenance in Salem, New Hampshire, collects grass on every one of his 66 properties he mows weekly. To pick up clippings during the mowing season and leaves in the fall, he uses a vacuum system. It works great for both applications, Linehan says, although he plans to upgrade from a system with an 11-hp engine and 8-inch hose to one that is powered by a 16-hp engine and uses a 10-inch hose. The additional power and an increased hose diameter will speed up the job and help with wet, heavy grass.

Other survey respondents reported using a Catcher Lift System from All Seasons. The lift system attaches to a Walker Mower and allows operators to empty directly into a truck, trailer, dumpster or over a fence to feed cows. Systems are available for Walker models C, D and T. Patented in 1993, there are now over 900 lift systems in use in 18 countries.

Operators looking for a cost-effective way to unload debris may want to take a tip from John Nompleggi, a contractor in Kennebunkport, Maine. Nompleggi started his business in 1995 and purchased his first Walker three years ago. “To facilitate unloading, we lay a tarp in our transport trailers and dump clippings/leaves on the tarp,” says Nompleggi. “At the landfill we drag the tarp off the trailer with the Walker. Dumping takes no more than 10 minutes. I simply tie a couple of ropes from the tarp to the Walker, and back the Walker and loaded tarp off the trailer.”

Operators looking for a cost-effective way to unload debris may want to take a tip from John Nompleggi, a contractor in Kennebunkport, Maine. Nompleggi started his business in 1995 and purchased his first Walker three years ago. “To facilitate unloading, we lay a tarp in our transport trailers and dump clippings/leaves on the tarp,” says Nompleggi. “At the landfill we drag the tarp off the trailer with the Walker. Dumping takes no more than 10 minutes. I simply tie a couple of ropes from the tarp to the Walker, and back the Walker and loaded tarp off the trailer.”

Dumping Fees

There are other costs associated with debris removal that go above and beyond the expense associated with handling debris on-site. The two biggest ones are dumping fees and travel time.

Nearly 50% of all survey respondents reported they are charged for taking debris to an off-site location. On average, they reported spending slightly more than $2,000 a year to dispose of the clippings. Contractors in the West and Northeast (spending $2,985.83 and $2,562.50, respectively) pay the most for debris removal.Those in the South Atlantic region (spending an average of $1,198 annually in dumping fees) pay the least.

More than 40% of contractor respondents indicated they travel six miles or more to dispose of debris. During peak mowing/leaf removal season, more than 50% of all survey respondents, including contractors, reported taking only one trip per day to the compost site or landfill. One-third of the respondents, however, take between two and five trips daily

When asked how may trips per year they would take to the compost site or landfill, 56% of contractors reported making more than 50 trips. Of these, 16% indicated they took between 100 and 200 trips; another 14% reported taking more than 200 trips a year.

For collecting debris, you can’t beat a Walker Mower. Its compact design and GHS collection system offers exceptional vacuuming action without compromising maneuverability. Yet, having a Walker Mower allows operators to win only half the debris battle, as explained by survey respondent Troy Robertson. “When I purchased my Walker, my only concern was how to handle the debris once I collected it. This is still a concern.” Currently, Robertson, who is located in Pratt, Kansas, handles clippings with a ramp system, but is always looking for ways to save more time and money. “For me,” he says, “it’s a matter of balancing the time and labor I spend handling debris against the cost.”

The same can be said for other Walker users. Handling clippings and other debris is a challenge no matter how big or small the operation is. Walker operators have the best machine on the market for collecting debris. Now, they have to find a debrishandling system that will allow them to further optimize handling capability.

As indicated in the above survey results, only a small percentage of Walker operators currently use a mechanical lift system or vacuum system to handle debris, and only 20% have streamlined the process with a ramp-to-truck or ramp-to-trailer system. That means close to 70% of Walker users still handle debris with their hands. There’s nothing wrong with that except that it takes time and labor to do this. And time and labor add up to money.

Before the mowing season rolls around this year, take a moment to evaluate your debris-handling process. Determine how much time you spend loading and unloading clippings and leaves. Factor in how many trips you make to the compost pile or landfill each day, how far you drive and how many trips you make in a year. Add up your time and expenses and then take a look at debris-handling systems on the market. Some options are more expensive than others, and each has its own advantages and disadvantages.

The combination trailers, for example, hold several cubic yards of debris (reducing the number of trips to the compost/landfill site) and can transport equipment, too. But they are expensive compared to other systems. Vacuum loaders are less costly, but they require enclosed trucks or trailers, which severely limits their use for transporting equipment.

The combination trailers, for example, hold several cubic yards of debris (reducing the number of trips to the compost/landfill site) and can transport equipment, too. But they are expensive compared to other systems. Vacuum loaders are less costly, but they require enclosed trucks or trailers, which severely limits their use for transporting equipment.

Ramp systems are inexpensive, but they require backing mowers onto trucks and/or trailers. As one survey respondent reported, the system doesn’t eliminate handling the debris by hand because grass and leaf piles still need to be relocated by hand to ensure a full load. Other systems such as the Catcher Lift System are gaining in popularity, as well.

In all cases, it’s a matter of balancing equipment costs against the time and labor associated with handling the debris. The system you select has to be both cost-effective and best suited for your application.

Site Search

Site Search