By most accounts Brian Larsen is a late bloomer in this industry. He left the forest business and a desk job at age 50, and purchased a tractor mowing company. Homeowner inquiries led him naturally to the landscaping industry where he now maintains three large residential locations, 20 to 25 smaller residences, three institutional sites, and four commercial properties.

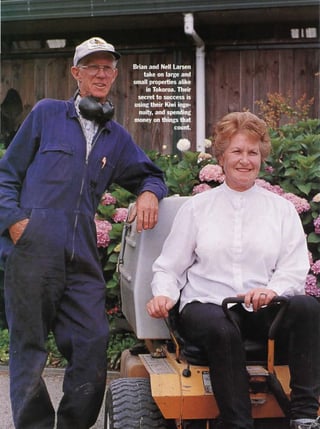

Larsen's business card lists an array of services, but mowing is the company's strong suit. With wife Nell, Larsen takes on large and small properties alike, delivering a high level of service and responsiveness that customers have come to expect. And that's no small feat in New Zealand where rainfall is plentiful and grass is cut naturally to within an inch of its life.

Larsen's business card lists an array of services, but mowing is the company's strong suit. With wife Nell, Larsen takes on large and small properties alike, delivering a high level of service and responsiveness that customers have come to expect. And that's no small feat in New Zealand where rainfall is plentiful and grass is cut naturally to within an inch of its life.

There are other challenges in this part of the world as well. The soil around Tokoroa where Larsen's Landcare is headquartered is volcanic, comprised of a pumice that literally eats away at mowing decks and blades.

Customers are few and far between, causing contractors to travel 31 miles or more to secure jobs. And costs of doing business are high. Larsen estimates that before he cranks his mowers up, 50% of his revenue is already accounted for in taxes and other overhead expenses. So how does he do it? With more than a little Kiwi ingenuity, and spending money on things that count.

Independent By Nature

New Zealanders, or Kiwis as they're also known, have always relied on their own creativity to survive. Isolated from the mainstream, they have had to "make do" with natural resources and wit to carry them through.

Larsen is no exception. His self-designed and custom-built trailer is a dead giveaway. This multi-purpose unit carries his hand tools and mowing equipment, and it also doubles as a loading/dump trailer. A spring-loaded platform effortlessly dumps clippings into a box that later tips backward to discard them into a compost pile or other disposal area. The trailer is designed to be towed easily by a 24-year-old Ford automobile. This is not your ordinary tow vehicle. But then again, Larsen is not your ordinary operator.

Among other things he uses a synthetic oil in his maintenance equipment that, he claims, allows him to extend change intervals but still receive optimal performance. Seeing is believing. One of his Walkers has 4,000 engine hours and is still cutting with the best of them.

Larsen also works to protect his mower blades by welding a sacrificial strip on the blade surface. The strip acts as a buffer between the blade and the pumice soil. Each blade receives three such strips before being replaced.

The special oil, trailer and blade arrangement are examples of not only Kiwi ingenuity but what this owner calls "spending money where it counts." His mowing equipment falls into the same category.

"When customers first asked me to mow, I tried out several machines," says Larsen. "They could all mow grass, but that was about all."

As he reports, many of his customers wanted their grass clippings picked up. The task proved a dual challenge for decks that at one and the same time had to cut close to the ground and pick up the clippings. Added to the mix was a rainy season that often left the grass wet during the day.

A Walker Mower with the GHS deck did the best job of any, he adds. He purchased his first one in 1988 and two more followed. Nell is right at home on one of the Walkers, Brian on another. A "casual" employee uses the third Walker that also acts as a spare.

As Larsen admits, Walker Mowers are not the cheapest mowers around, so operators have to receive a respectable hourly rate to justify them. But the end result speaks for itself.

"If I can get on the job with the mower and show property owners what it will do, I can get the job," he emphasizes.

Larsen mows his accounts every two weeks for eight months out of the year and backs off during the winter season by mowing them once a month or every six weeks. Although New Zealand grass doesn't turn brown in the winter, it does go through a dormant stage. The slowed growth gives Larsen time to catch up on pruning, and is ideal for planting shrubs and other landscape elements.

But in the spring and summer it's full speed ahead for the grass and operators who mow it. Larsen's team was currently mowing a large horse farm, a configuration that put the Walker's versatility to a test, as well. Wide areas and long grassy strips are complemented by finely manicured parade and viewing areas. The entire project would take Larsen and his wife 10 hours to complete.

Larsen turns his head to give Nell a glance. She's operating the Walker like the professional she is, wasting no time maneuvering around trees and going down the straight-aways.

Larsen turns his head to give Nell a glance. She's operating the Walker like the professional she is, wasting no time maneuvering around trees and going down the straight-aways.

"Nell does a great job of mowing," says Larsen. "In fact, I prefer women operators to men. They are easier on the equipment and they are more fastidious about the job they do."

After all, the bottom line for any maintenance contractor is getting the job done in the most productive way possible, and having an end-product that can't be surpassed. Whether or not one calls it Kiwi ingenuity, spending money on things that count, or just plain common sense, it all adds up the same way.

Site Search

Site Search