If you're like most lawn maintenance professionals, you started your business using one or two walkbehind mowers. And if you're like most successful entrepreneurs, your business has grown to the extent you now need to purchase additional mowing equipment. Should you buy more walk-behinds, or is it time to consider one of those expensive riders you see some of your competitors using? The answer may surprise you.

Overcoming Sticker Shock

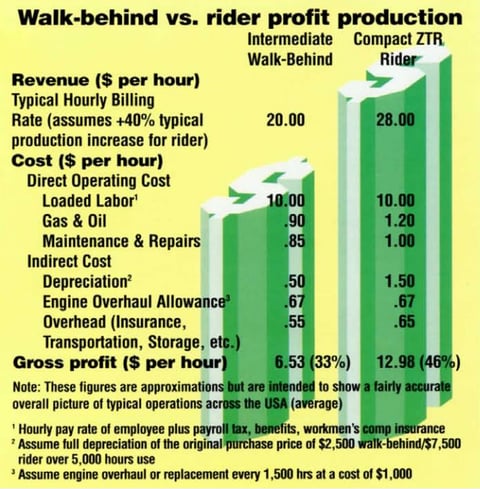

An immediate objection to a rider is the purchase price. "I can buy two or three walk-behinds for the price of one rider" is the common reaction. To get a true perspective of the cost of a piece of equipment, however, the purchase cost must be spread out over the useful life of the equipment (see accompanying chart).

Assume the difference in purchase price between an intermediate walk-behind and a zero-turn rider is $5,000. That's a lot of money. But when this figure is depreciated over the life of the equipment (5,000 hours), it would cost only $1.00 per hour more to operate a rider compared to a walk-behind. This does not take into consideration other direct and indirect operating costs, only depreciation. Adding in direct operating costs such as fuel, oil, maintenance and repairs and indirect costs such as insurance, transportation and storage, the cost goes up only another 55 cents per hour, for a total of $1.55 per hour more to operate a rider. Probably not as much as you thought.

Of course, your business will need to have enough cash flow to purchase the new rider outright or to service monthly payments on a lease or installment purchase.

Rider Rationale

The above additional cost may not seem like much to operate a rider and it isn't. But in the competitive lawn maintenance business, a dollar saved is literally a dollar earned. If a rider can't increase your hourly output, then there really is no reason to buy one.

As indicated above, both direct and indirect operating costs are higher for a rider. But so is a rider's productivity - to the tune of better than 40 percent according to most industry experts. If you normally bill $20 per hour for your walk-behind, a rider (see chart) should be able to earn $28 for that same hour. The increase easily offsets the initial cost of the rider and operating expenses.

In fairness, production gains with a rider will vary, depending on the type of mowing job. While the 40 percent figure is an average gain commonly reported by rider owners, each mowing application needs to be examined to see if a rider is actually faster. On some jobs, of course, a walk-behind is the only choice because of terrain and size of properly.

How does a rider cover more ground than a walk-behind mower when the ground speeds of both are about the same? Mowing speed is not all ground speed. Mowing speed depends in large part on a machine's maneuverability, trimming capability, and ability to minintize lost motion and reduce operator fatigue. A compact zero-turn rider holds the overall speed advantage in most mowing applications where both a rider and a walkbehind could be used.

The Human Element

Labor is the biggest factor in producing mowing revenue. Contractors build profit by increasing labor output. Again, although all costs are important in any mowing operation, labor is the biggest expense by far. As the chart indicates, labor is anywhere from 10 to 20 times more costly than other operating expenses, and taken as a whole it dwarfs the additional $1.55 per hour it costs to operate a rider.

The moral? Using labor productively is the most important variable to be considered when selecting equipment. It has been said (and proven hundreds of times over) the difference between a good and bad employee is much greater than the difference between a good and bad piece of equipment. The secret to success in this business is to "weed and feed" employees (weed out the bad ones and give your good ones incentives) - and find your good employees, the most productive equipment for the job.

Intangibles Point To Riders, Too

When used in the right application, a compact zero-turn rider will allow you to do more work with less equipment, and it will reduce operator fatigue. A rider will produce more revenue and drop more to the bottom line. That says a lot for any piece of equipment. But there are other considerations, too.

Just having fewer machines to transport, store, carry parts for and maintain is a cost savings. Then there are employee training costs to consider. If a rider reduces employee turnover, it reduces training costs and the expenses associated with advertising for and hiring new employees. Also. in a tight labor market, riders open the labor pool to people other than 20-year-old athletic types needed for walk-behinds. Generally speaking, hourly pay rates for physically demanding work (e.g., operating a walk-behind mower) are higher, too.

One last point to consider. Perception is reality. Customers oftentimes judge a maintenance company by the equipment it brings to the site. An intangible to be sure; it can be argued, however, that a compact zero-turn rider projects a better, more professional image than a walk-behind mower. It just might be the thing that tips a bid in your favor, especially if you're bidding against a competitor with walk-behind mowers.

Site Search

Site Search