Picture what the country's largest, gated retirement community looks like. Then superimpose a spectacular setting in Southern California. The image would be Leisure World where 20,000 residents enjoy a living environment second to none.Imagine theaters, 27 holes of golf, tennis courts, riding stables, arts and crafts along with wood and machine shops, a radio station and newspapers, not to mention two dedicated garden centers and a bus line. There's a library, too, and boccie ball courts, lawn bowling... and the list goes on.

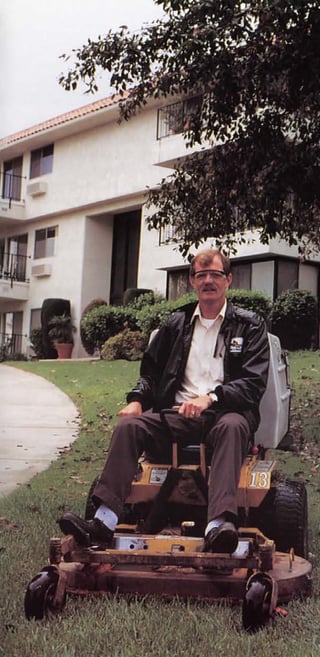

Imagine, too, 450 acres of turf to mow every week, 52 weeks out of the year and enough trees to rival some national parks. Then there is the equipment to maintain the landscape and the people to operate and maintain the equipment. All of this is orchestrated from the office of landscape operations supervisor John Berne who, in some ways, resembles a factory manager. In this case he's managing the mowing and growing of grass instead of overseeing the manufacturing process. The company he works for, Professional Community Management (PCM), is contracted as the managing agent for Leisure World at Leguna Hills. PCM takes care of all of the retirement community's manpower needs.

Imagine, too, 450 acres of turf to mow every week, 52 weeks out of the year and enough trees to rival some national parks. Then there is the equipment to maintain the landscape and the people to operate and maintain the equipment. All of this is orchestrated from the office of landscape operations supervisor John Berne who, in some ways, resembles a factory manager. In this case he's managing the mowing and growing of grass instead of overseeing the manufacturing process. The company he works for, Professional Community Management (PCM), is contracted as the managing agent for Leisure World at Leguna Hills. PCM takes care of all of the retirement community's manpower needs.

Berne moved to Southern California from his native Ohio in 1981. He took a job at Leisure World as an air-cooled engine mechanic and moved quickly up the ranks to landscape operations supervisor. Inventory control, the shop area and recycling also came under his supervision.

Berne rattles off inventory like he's been counting equipment instead of sheep at night. ''Forty backpack blowers, 15 reciprocating trimmers, 15 weed caters, 80 hedge trimmers, 35 edgers, 20 vacuums, 70 hand blowers, 20 push mowers and 40 Walkers." There's more, he adds, including four Kubota tractors with 60-inch decks for mowing rough areas, bringing the total to more than 480 pieces of lawn maintenance equipment alone. The landscape department employs 200 people. including those who work in pest control, irrigation, lawn maintenance, recycling, golf course maintenance and the equipment shop, and the arborists.

The Grass Business

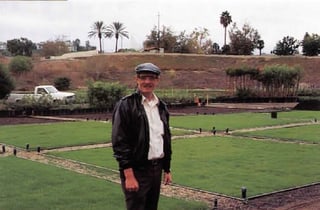

To say Berne is in the grass business is an understatement. It takes nine maintenance crews to mow Leisure World. A mowing cycle is completed in four and one-half days. When clippings and leaves are collected, the debris is taken to an in house composting facility that on average recycles 150 yards a day. The green waste is turned into compost to be used for mulching flower beds and control of weeds, for potting soil and to grow soilless sod.

Like all good managers and supervisors. Berne earns his keep by employing procedures that will improve the end product while reducing costs. Composting, for example, has saved Leisure World hundreds of thousands of dollars in dump fees, Berne notes. “The recycling process also provides mulch which reduces water requirements and keeps the weeds down. Plants, in turn, are healthier which means we have to spend less money on pesticides."

The same logic applies to the mowing operation.

"When I first came to Leisure World, we had a mowing cycle of 12 days," tells Berne. The never-ending task was tackled using a collection of 70 to 80 push mowers and walk behind mowers and eight riding mowers.

“We bought our first Walker, in fact our first eight Walkers in 1987," he relates. "At the time, we were a community of 11,000 backyards. We originally wanted the Walkers to replace our other riders which couldn't fit in some of the tight area .

“We bought our first Walker, in fact our first eight Walkers in 1987," he relates. "At the time, we were a community of 11,000 backyards. We originally wanted the Walkers to replace our other riders which couldn't fit in some of the tight area .

What we discovered was they could also go place our 36-inch walk-behinds with grass catchers couldn't."

Berne explains they didn't jump right on the Walker bandwagon, however, because they wanted to see how the mower would hold up. "One of our concern with any new piece of equipment is maintenance cost," he explains. "When we found maintenance on the Walkers to be low, we bought more."

More indeed! The landscape department has peaked out with 40 Walker mowers. Each is equipped with a 42-inch deck and grass handling system and powered by a 16-hp Kohler. The move to Walker has dramatically reshaped landscape operations. The mowing cycle has been substantially reduced and gone are all of the intermediate walk mowers, although the department still has 20 or so 21-inch mowers, "collecting dust," Berne adds. Maintenance costs as well as mowing time have gone down, too. There are now only four mechanic in the department compared to six when Berne came on board.

Making the Grade

Despite their week-long, year round work cycle, Berne' mowers are expected to last five years, which helps him continue to keep costs in line. They're also expected to perform in other areas.

Part of Leisure World's charm is its setting. Hills, as in Laguna Hills, dominate the landscape and add another twist to the already challenging landscape maintenance operation.

"Having so many acres to mow makes us a convenient target for manufacturers who want to get their mowers in here," Berne explains. "We try them all and none of them negotiate the hills like our Walkers can because they have such a low center of gravity. In fact, a few years ago a company brought out a prototype of a new model, and it just slid right off a 20-degree slope. That was the end of the demonstration since our mowers have to handle those grades on a daily basis."

"Having so many acres to mow makes us a convenient target for manufacturers who want to get their mowers in here," Berne explains. "We try them all and none of them negotiate the hills like our Walkers can because they have such a low center of gravity. In fact, a few years ago a company brought out a prototype of a new model, and it just slid right off a 20-degree slope. That was the end of the demonstration since our mowers have to handle those grades on a daily basis."

Leisure World's Walkers can do more than climb and outcut intermediate mowers. Ten of them, for example, are equipped with custom-made disc/blade combinations that chip and collect branches up to 1 inch in diameter. Berne claims the innovation saves 14 percent during the pruning cycle. That's a sizable saving, considering the number of people who participate in the operation.

Decks are also equipped with a quick-change gate that, with a flip of lever, transform the mower from a mulcher to a collector. "We like to mulch or grasscycle as much as we can," Berne relates. "Since clippings are comprised of 80 percent water and 4 percent nitrogen, returning them to the soil also gives back much needed nutrients and water. But residents don't like to see leaves, and leaves are constantly falling around here. So crews mulch when they can and simply flip the lever when they see debris that needs to be collected."

Leisure World Walkers are also equipped with electric fertilizer spreaders. Operators simply slip a couple bags of fertilizer in the grass collector and off they go.

It all comes back to finding way to reduce costs while still maintaining a high level of service. To be sure. since its inception 29 years ago, Leisure World has developed the reputation as one of the premier planned retirement communities in the country. Built in three phases, the complex features single family homes, duplexes and garden homes, the residents of which average nearly 76 years of age. In addition to a long list of services and activities, residents can also take advantage of six clubhouses and swimming pools. There's also a nature trail inhabited by waterfowl, eagles and a roadrunner or two.

Yet despite it size and number of employees, the landscape operation maintains a relatively low profile, thanks in large part to careful planning and instituting small efficiencies that really add up.

Few lawn maintenance contractors and operators around the country can identify with the size of Leisure World's landscape operation. Fewer still produce as much grass as Leisure World where just about everything is done on a large scale. But all contractors can appreciate productivity and how one right move leads to others.

Site Search

Site Search