M any larger contractors employ in-house technicians who repair everything from string-line trimmers to the company dump trucks. Other larger companies "contract out" service on their fleet truck, yet still maintain their lawn equipment lineup.

Employing a part-time technician works for many smaller companies while others forego the technician route in favor of "handy" crew members or an owner/operator with technical ability. And some smaller companies simply leave the service and repair to their dealers.

Employing a part-time technician works for many smaller companies while others forego the technician route in favor of "handy" crew members or an owner/operator with technical ability. And some smaller companies simply leave the service and repair to their dealers.

What is the most cost-effective way to maintain equipment? That depends on your capabilities and those of your independent dealer. A strong case can be made for using a combination of both techniques.

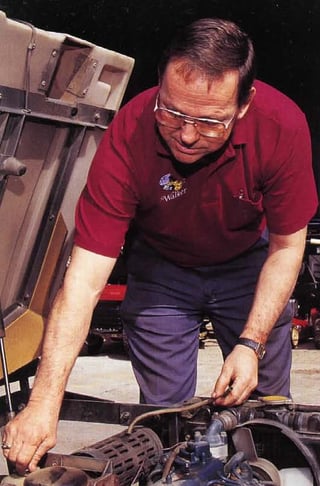

Wrenching In-House

There's no question, having an in-house technician can save both time and money. It takes time to drop off and pick up equipment at a dealer's location. And most commercial dealers, no matter how dedicated they are to serving their professional customers, still require some turnaround time. The $40/hour price tag that comes with dealer shop time can also be discouraging.

Preventive maintenance service - as long as it follows a manufacturer's specifications - can usually be done cost-effectively in-house. Oil and filter changes, lubrication, belt tightening, and blade sharpening and changing are all services that can be performed with basic tools and a baseline of power equipment knowledge. Minor repairs such as replacing belts and mufflers, fixing tires, replacing wheel bearings and even welding up mowing decks can also be done in-house with some expertise and the right equipment. Companies with trained, experienced technicians and the right tools, on the other hand, may have the ability to perform nearly any repair service.

Again, wrenching in-house has its advantages. Equipment can be fixed in a timely fashion and the shop rate is reasonable. But it has its downside.

Repairs done by inexperienced employees can be expensive in the long run, in the form of additional parts pickup trips and more repair time that leads to increased downtime. Even experienced technicians may not be "up to speed" in every repair procedure.

Other disadvantages? For smaller companies, there just isn't enough work to accommodate a full-time technician. And even larger companies are often forced to find "odd jobs" to fill in a technician's time sheet. The more downtime a technician has, the more it will ultimately cost to perform service and repair.

The Dealer Advantage

By far, the biggest advantage dealers have over in-house repair is their experience and expertise. Servicing dealers perform countless repair procedures. This means they can generally perform repairs faster than in-house mechanics, and with better success rates.

The two Es - experience and expertise - are especially important when talking about some of the higher-tech equipment on the market. While a simple electrical problem may baffle an in-house technician for hours, a dealer- with factory spec sheets, wiring diagrams, service bulletins and conceivably previous experience with the specific problem -may take only minutes.

Also, new emission standards for hand-held equipment nearly mandate that units be taken back to the dealer for some types of repair and/or adjustment.

The truth is, we live in a specialized world today. A technician is not just a technician. He or she is trained in a specific industry to diagnose and repair sophisticated equipment. Dealers spend literally thousands of dollars annually to send technicians to service schools, and spend even more money on tools and equipment. The end result is better service for the customer.

Successful commercial dealers are really in business to make life easier for their commercial customers. They find ways to minimize their customers' downtime and keep them in the field where they belong. Hence, dealer service often includes 24- to 48-hour turnaround, the use of a loaner, and agreeable business hours that allow customers to bring in repair problems either early in the morning or late in the afternoon.

Yes, it sometimes pays to perform the service or repair in the convenience of your own shop. But don't get caught in the trap of thinking that just because you and your technicians do some of the service and repair work that all of it can be done cost-effectively in-house. Lawn maintenance professionals need to strike a balance between in-house repair and dealer service. They shouldn't shy away from repairs that can be done affordably and in a timely fashion in-house or attempt to do everything themselves.

Take a moment this winter to assess your repair needs. It might even pay to determine how much money you spent on repairs last year- at your dealer and in-house. Be sure to add in travel costs to and from your dealer and time spent internally on repairs. You may be surprised to learn that, in many cases, the $40/hour shop rate is not a bad deal, especially if it saves on downtime and return trips for parts.

Site Search

Site Search