We all know how important it is to make a profit. Without a consistent and healthy bottom line, any business will eventually dry up and die. But making a profit isn’t the only top priority for Walker Mower users, or any mowing contractor for that matter.

Even more important than profit is being safe while making that profit. All the money in the world won’t make up for a serious injury. The truth is, those contractors who operate in a safe manner and properly train their employees are likely to be among the most profitable business owners in the industry.

Having safety meetings and ongoing safety training is fundamental to keeping loss-time injuries and insurance costs to a minimum, reducing damage to equipment, and losing time on the job. Furthermore, clients don’t want unsafe companies working for them, and good employees shy away from an unsafe work environment.

Our industry has plenty of room for improvement in this area as it has one of the highest OSHA (Occupational Safety and Health Administration) hazard rates in the United States. One of the biggest reasons for this is lack of training, as indicated by figures that show most injuries occur in the early spring and during the first 12 months of employment, when new and inexperienced employees are operating equipment. With that said, it is imperative for operators of any brand of mowers to have proper training before taking the equipment into the field.

The following should be included as part of Walker Mower training for all of your employees, because even veterans need to be reminded about the do’s and don’ts of operating in a safe manner.

Controls

Familiarize operators with controls, paying special attention to the operation of the Forward Speed Control (FSC) and steering levers on the Walker Mower. Make sure everyone understands that moving the FSC to the neutral position will stop the mower, and instruct operators to use only their left hand to operate steering levels. Using both hands will cause over-steering.

Point out the safety interlock systems and how they work. The mower will not start unless the FSC is in the neutral position and the PTO is disengaged. A seat safety switch kills the engine if the operator dismounts when the FSC is not in the neutral position or the PTO is engaged. Remind operators to always check to make sure the PTO has stopped rotating before dismounting the mower.

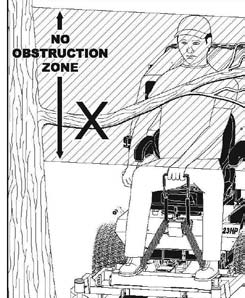

Instruct operators to give their mowers a “once-over” before going to the field, to make sure all safety devices are working correctly and shields are in place. Test the operation of the seat safety switch by lifting off of the seat with the mower blades engaged and making sure the engine stops. Operators should also be wearing eye and ear protection, along with substantial footwear. Loose-fitting clothing is not appropriate since it can catch on branches or impede the safe operation of the mower.

Instruct operators to give their mowers a “once-over” before going to the field, to make sure all safety devices are working correctly and shields are in place. Test the operation of the seat safety switch by lifting off of the seat with the mower blades engaged and making sure the engine stops. Operators should also be wearing eye and ear protection, along with substantial footwear. Loose-fitting clothing is not appropriate since it can catch on branches or impede the safe operation of the mower.

Operation

Have your inexperienced operators practice in an open area away from buildings, fences and obstructions before actually mowing. Until familiar with all operating characteristics of the mower, they should maneuver with a slow engine speed and slow FSC setting. Impress upon them that for an emergency stop or in case of loss of control, simply pulling the FSC into the neutral-park position will quickly stop the mower.

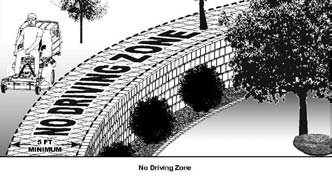

Once employees become absolutely comfortable with the Walker Mower’s operation, it’s time to put the machine to good use. Before mowing, properties should be policed for objects that may be thrown by the blades. Furthermore, operators should become acquainted with steep hills, drop-offs and other potential hazards. Operators need to avoid mowing close to ponds, streams and retaining walls. These areas are more suitably mowed with a walkbehind mower or string-line trimmer.

Once employees become absolutely comfortable with the Walker Mower’s operation, it’s time to put the machine to good use. Before mowing, properties should be policed for objects that may be thrown by the blades. Furthermore, operators should become acquainted with steep hills, drop-offs and other potential hazards. Operators need to avoid mowing close to ponds, streams and retaining walls. These areas are more suitably mowed with a walkbehind mower or string-line trimmer.

The Walker Mower has a low center of gravity and superior traction, thanks to the balance provided by its front-cut design. Both characteristics allow it to mow safely on relatively steep slopes. However, never operate on a hill or slope with an angle greater than 20 degrees or 33-percent grade. Make sure employees understand how the “degrees” and “percentages” translate into actual mowing conditions by pointing out safe and less-than-safe slopes. When mowing on any slope, being cautious, reducing travel speeds and avoiding sharp turns are requisites. Also remind operators that before dismounting from the mower on a slope, always engage the parking brake.

Other Safety Reminders

If your Walker Mower is equipped with a side-discharge deck, the discharge chute needs to be in place at its lowest position and pointed away from sidewalks and streets. If using a GHS deck, the catcher door needs to be closed while mowing. Instruct new employees on how to unclog material from the discharge chute on a GHS mower. They must never use their hands; a stick or other tool will get the job done. Make sure the PTO drive shaft has stopped moving before unclogging.

To help with your training, Walker Manufacturing offers a “How to Mow/ How to Maintain” DVD presented in both English and Spanish. As always, the Operator’s Manual is required reading before operating any new piece of equipment. Remember, too, that employees learn by observing. Operating equipment safely will set a good example for employees. Conversely, if you’re ignoring safety issues, your employees likely will do the same.

Having a safe work environment begins at the top of any organization. Hold safety meetings, be a good instructor and make employees accountable for following safe operating procedures. It’s good for them, and good for your bottom line.

Site Search

Site Search